close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

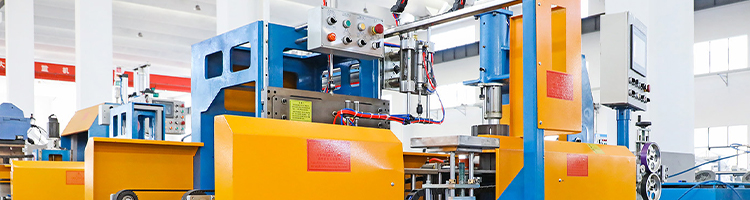

The Semi-Automatic Vertical PP PVC Steel Coil Wrapping Machine is a space-saving packaging solution designed for PP/PVC-coated steel coils and bare steel coils. Its vertical structure reduces floor space by 60% compared to horizontal models, while the semi-automatic operation balances efficiency and cost-effectiveness—ideal for small-to-medium batch production . Equipped with a high-torque winding motor and adjustable tension control, it applies stretch film or VCI anti-rust paper evenly around steel coils weighing up to 1000kg, protecting against corrosion and transportation damage. It has become essential for steel processors and cable manufacturers, complying with ISO 9001 packaging standards and GB/T 24490 rust prevention requirements.

Adopts a vertical turntable design with a minimum footprint of 1.2m×1.5m, fitting into compact workshops or production lines with limited space .

Manual coil loading (with optional hydraulic lift assist) and automatic film winding—reducing labor requirements to 1 operator per machine, lowering staffing costs by 50%.

Features a servo-controlled winding head with adjustable speed (5-18r/min) and film overlap (20%-60%), ensuring 360° coverage even for irregularly shaped steel coils .

Built-in tension sensor that maintains consistent film tightness (0.5-5kg) to avoid coil deformation while preventing moisture ingress—reducing rust defects by 40%.

Turntable made of 16mm thick carbon steel with anti-slip surface, supporting maximum coil diameter of 1200mm and weight up to 1000kg .

Compatible with multiple packaging materials: 500mm-1000mm width stretch film, VCI anti-rust paper, and reinforced kraft paper for outdoor storage.

Steel Processing: Wraps PP-coated steel coils for construction reinforcement, preventing coating scratches during transit.

Cable Manufacturing: Packages PVC-insulated steel wire coils (e.g., welding cables) with VCI paper to resist corrosion in coastal storage facilities.

Hardware Distribution: Protects small-batch bare steel coils (≤500kg) for retail delivery, enhancing product presentation and reducing returns.

Medium-sized steel workshops producing 500-800 coils/month, using semi-automatic operation to avoid overinvesting in full automation.

Cable factories with mixed batch sizes, leveraging quick parameter adjustment to switch between 400mm and 1200mm diameter coils in 5 minutes.

Outdoor storage yards wrapping steel coils with kraft paper and stretch film, achieving 6-month rust-free storage in humid environments.

How many operators are needed for the machine?

Only 1 operator—responsible for loading coils (with optional hydraulic lift) and starting the wrapping program; the machine automatically stops when wrapping is complete.

What is the hourly wrapping capacity?

For 800mm OD coils, it wraps 40-60 coils per hour—suitable for small-to-medium production volumes without sacrificing efficiency.

How to maintain rust prevention effectiveness?

Use VCI film with the machine’s recommended 40% overlap; replace the tension sensor’s dust cover monthly to ensure accurate tightness control.

Can it handle heavy coils safely?

Yes, the reinforced turntable supports up to 1000kg and is equipped with anti-tip guards; the emergency stop button cuts power instantly if anomalies occur .

| Height H (mm) | Outside Diameter O.D ( mm ) | Inside Diameter I D (mm) | Wire/Cable Diameter (mm) | Average output ( 100M / Coil ) |

CP1040 | 50-100 | Ø180-Ø400 | Ø120-Ø200 | Ø3 - Ø 8 | 2Coils/Min. |

CP1860 | 70-150 | Ø280-Ø600 | Ø180-Ø250 | Ø5 - Ø 15 | 1Coils/Min. |

The Semi-Automatic Vertical PP PVC Steel Coil Wrapping Machine is a space-saving packaging solution designed for PP/PVC-coated steel coils and bare steel coils. Its vertical structure reduces floor space by 60% compared to horizontal models, while the semi-automatic operation balances efficiency and cost-effectiveness—ideal for small-to-medium batch production . Equipped with a high-torque winding motor and adjustable tension control, it applies stretch film or VCI anti-rust paper evenly around steel coils weighing up to 1000kg, protecting against corrosion and transportation damage. It has become essential for steel processors and cable manufacturers, complying with ISO 9001 packaging standards and GB/T 24490 rust prevention requirements.

Adopts a vertical turntable design with a minimum footprint of 1.2m×1.5m, fitting into compact workshops or production lines with limited space .

Manual coil loading (with optional hydraulic lift assist) and automatic film winding—reducing labor requirements to 1 operator per machine, lowering staffing costs by 50%.

Features a servo-controlled winding head with adjustable speed (5-18r/min) and film overlap (20%-60%), ensuring 360° coverage even for irregularly shaped steel coils .

Built-in tension sensor that maintains consistent film tightness (0.5-5kg) to avoid coil deformation while preventing moisture ingress—reducing rust defects by 40%.

Turntable made of 16mm thick carbon steel with anti-slip surface, supporting maximum coil diameter of 1200mm and weight up to 1000kg .

Compatible with multiple packaging materials: 500mm-1000mm width stretch film, VCI anti-rust paper, and reinforced kraft paper for outdoor storage.

Steel Processing: Wraps PP-coated steel coils for construction reinforcement, preventing coating scratches during transit.

Cable Manufacturing: Packages PVC-insulated steel wire coils (e.g., welding cables) with VCI paper to resist corrosion in coastal storage facilities.

Hardware Distribution: Protects small-batch bare steel coils (≤500kg) for retail delivery, enhancing product presentation and reducing returns.

Medium-sized steel workshops producing 500-800 coils/month, using semi-automatic operation to avoid overinvesting in full automation.

Cable factories with mixed batch sizes, leveraging quick parameter adjustment to switch between 400mm and 1200mm diameter coils in 5 minutes.

Outdoor storage yards wrapping steel coils with kraft paper and stretch film, achieving 6-month rust-free storage in humid environments.

How many operators are needed for the machine?

Only 1 operator—responsible for loading coils (with optional hydraulic lift) and starting the wrapping program; the machine automatically stops when wrapping is complete.

What is the hourly wrapping capacity?

For 800mm OD coils, it wraps 40-60 coils per hour—suitable for small-to-medium production volumes without sacrificing efficiency.

How to maintain rust prevention effectiveness?

Use VCI film with the machine’s recommended 40% overlap; replace the tension sensor’s dust cover monthly to ensure accurate tightness control.

Can it handle heavy coils safely?

Yes, the reinforced turntable supports up to 1000kg and is equipped with anti-tip guards; the emergency stop button cuts power instantly if anomalies occur .

| Height H (mm) | Outside Diameter O.D ( mm ) | Inside Diameter I D (mm) | Wire/Cable Diameter (mm) | Average output ( 100M / Coil ) |

CP1040 | 50-100 | Ø180-Ø400 | Ø120-Ø200 | Ø3 - Ø 8 | 2Coils/Min. |

CP1860 | 70-150 | Ø280-Ø600 | Ø180-Ø250 | Ø5 - Ø 15 | 1Coils/Min. |