close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

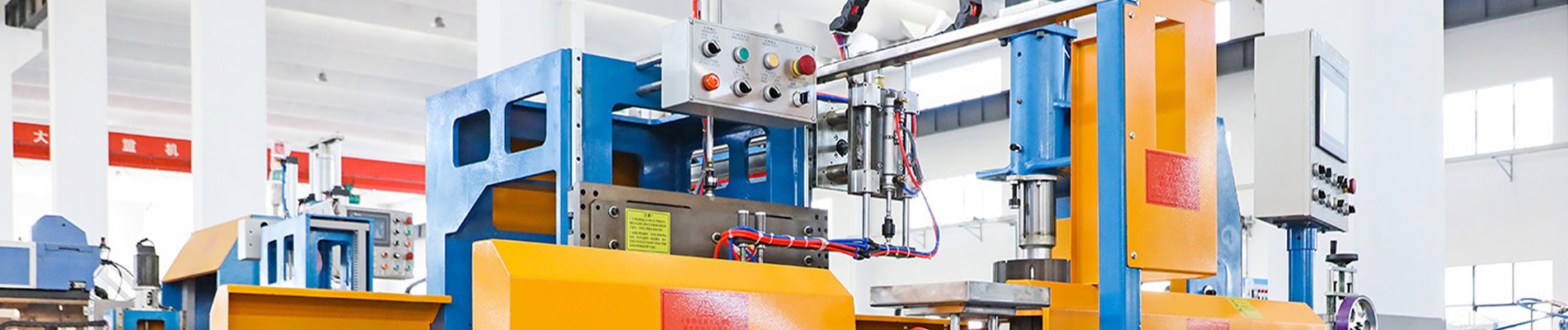

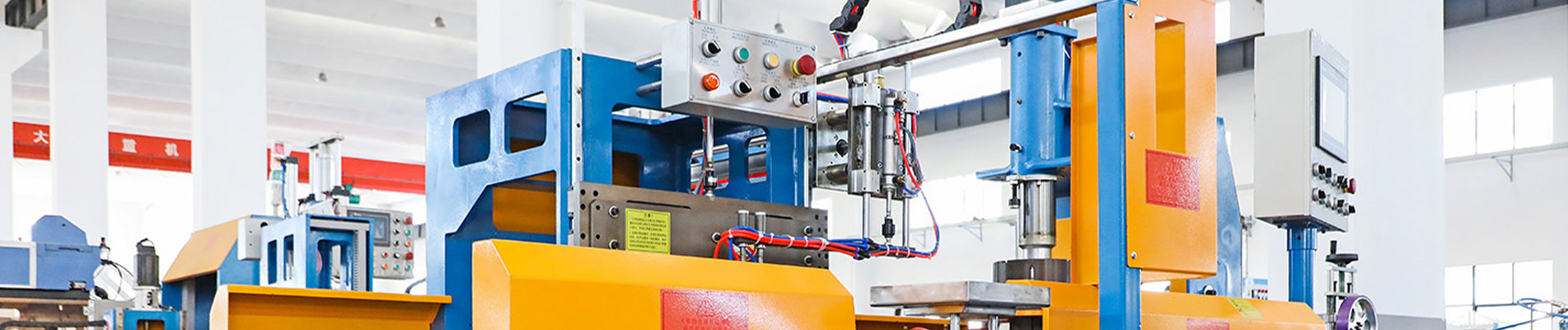

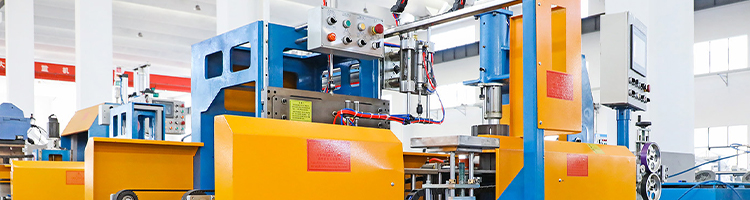

The High-Speed PVC PE UPVC Durable Cable Extruder Machine is engineered for ultra-fast production of cable insulation and jackets using PVC, PE, and UPVC (unplasticized polyvinyl chloride) materials. Its core advantage lies in the reinforced extrusion system that achieves a maximum output of 280kg/h for PE materials—double the speed of standard models —while maintaining structural durability for 24/7 operation. Equipped with a wear-resistant nitrided screw and high-temperature stable heating system, it addresses UPVC’s high viscosity challenge through precise shear control, making it ideal for manufacturers targeting high-volume orders in construction and industrial wiring. It complies with global standards including EN 50267 and GB/T 8815.

Features a 35:1 L/D ratio screw (SJ120 model) with triple-flight design, increasing material conveying efficiency by 60% and enabling UPVC processing at 180℃-210℃ without thermal degradation .

8-zone ceramic heating system (total power 37kW) with PID precision control (±0.5℃), paired with water-cooled barrel sections to maintain stable melt temperature during 24-hour runs .

Screw and barrel made of 38CrMoAlA alloy steel with 0.15mm nitrided layer (HRC ≥65), resisting abrasion from UPVC’s filler content for 40,000 hours of service .

Heavy-duty H-shaped steel frame with integral casting base, reducing vibration by 60% even at maximum extrusion speed (45m/min traction) .

Construction Wiring: Produces UPVC-insulated rigid cables for building electrical systems, complying with GB 50303 fire safety requirements.

Industrial Cables: Extrudes thick-wall PE jackets (5mm-12mm) for heavy-duty machinery cables resistant to oil and abrasion.

Municipal Engineering: Manufactures PVC-insulated power cables for urban grid renovation projects, leveraging high speed to meet large-order delivery deadlines.

Large-scale cable manufacturers with 800,000km/year capacity, using 24/7 operation to fulfill government infrastructure contracts.

UPVC cable production lines for residential construction, where the machine’s durability reduces maintenance downtime to less than 2 hours/month.

Emergency cable supply for power outages, utilizing 45m/min traction speed to produce 20km of PE-insulated cable per day.

Why can it process UPVC at high speed?

The triple-flight screw creates gentle shear to prevent UPVC degradation, while the 8-zone heating system maintains stable temperature—avoiding the carbonization issues common in standard extruders .

What is the actual production efficiency for large orders?

For 10mm diameter PE cables, it produces 16,200 meters per 8-hour shift (45m/min × 480min), 30% faster than competitors.

How long does the nitrided screw last?

Under normal UPVC processing conditions, the screw maintains precision for 40,000 hours—twice the lifespan of standard chrome-plated screws .

What maintenance is required for 24/7 operation?

Daily checks of heating zone temperatures and lubrication of traction gears; monthly replacement of the 150-mesh extrusion filter; annual overhaul of the gear reducer.

The High-Speed PVC PE UPVC Durable Cable Extruder Machine is engineered for ultra-fast production of cable insulation and jackets using PVC, PE, and UPVC (unplasticized polyvinyl chloride) materials. Its core advantage lies in the reinforced extrusion system that achieves a maximum output of 280kg/h for PE materials—double the speed of standard models —while maintaining structural durability for 24/7 operation. Equipped with a wear-resistant nitrided screw and high-temperature stable heating system, it addresses UPVC’s high viscosity challenge through precise shear control, making it ideal for manufacturers targeting high-volume orders in construction and industrial wiring. It complies with global standards including EN 50267 and GB/T 8815.

Features a 35:1 L/D ratio screw (SJ120 model) with triple-flight design, increasing material conveying efficiency by 60% and enabling UPVC processing at 180℃-210℃ without thermal degradation .

8-zone ceramic heating system (total power 37kW) with PID precision control (±0.5℃), paired with water-cooled barrel sections to maintain stable melt temperature during 24-hour runs .

Screw and barrel made of 38CrMoAlA alloy steel with 0.15mm nitrided layer (HRC ≥65), resisting abrasion from UPVC’s filler content for 40,000 hours of service .

Heavy-duty H-shaped steel frame with integral casting base, reducing vibration by 60% even at maximum extrusion speed (45m/min traction) .

Construction Wiring: Produces UPVC-insulated rigid cables for building electrical systems, complying with GB 50303 fire safety requirements.

Industrial Cables: Extrudes thick-wall PE jackets (5mm-12mm) for heavy-duty machinery cables resistant to oil and abrasion.

Municipal Engineering: Manufactures PVC-insulated power cables for urban grid renovation projects, leveraging high speed to meet large-order delivery deadlines.

Large-scale cable manufacturers with 800,000km/year capacity, using 24/7 operation to fulfill government infrastructure contracts.

UPVC cable production lines for residential construction, where the machine’s durability reduces maintenance downtime to less than 2 hours/month.

Emergency cable supply for power outages, utilizing 45m/min traction speed to produce 20km of PE-insulated cable per day.

Why can it process UPVC at high speed?

The triple-flight screw creates gentle shear to prevent UPVC degradation, while the 8-zone heating system maintains stable temperature—avoiding the carbonization issues common in standard extruders .

What is the actual production efficiency for large orders?

For 10mm diameter PE cables, it produces 16,200 meters per 8-hour shift (45m/min × 480min), 30% faster than competitors.

How long does the nitrided screw last?

Under normal UPVC processing conditions, the screw maintains precision for 40,000 hours—twice the lifespan of standard chrome-plated screws .

What maintenance is required for 24/7 operation?

Daily checks of heating zone temperatures and lubrication of traction gears; monthly replacement of the 150-mesh extrusion filter; annual overhaul of the gear reducer.