close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

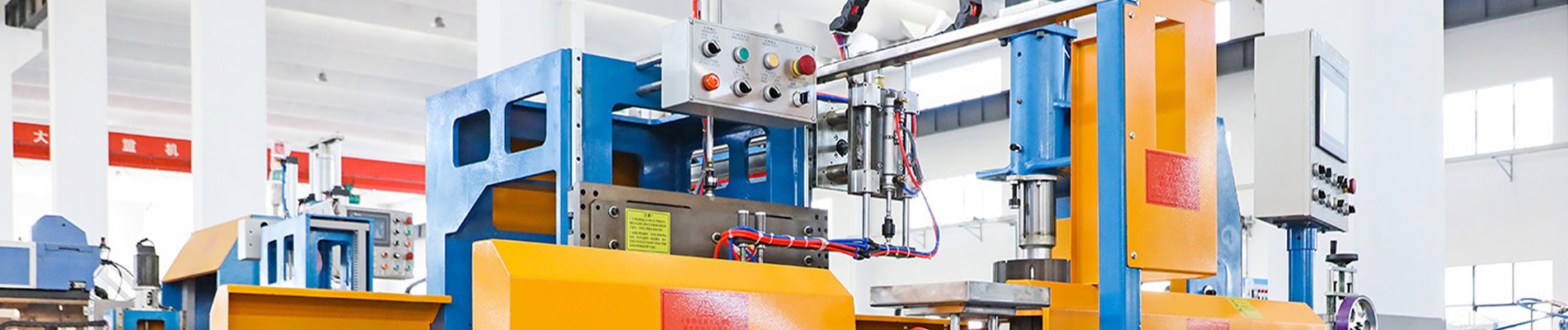

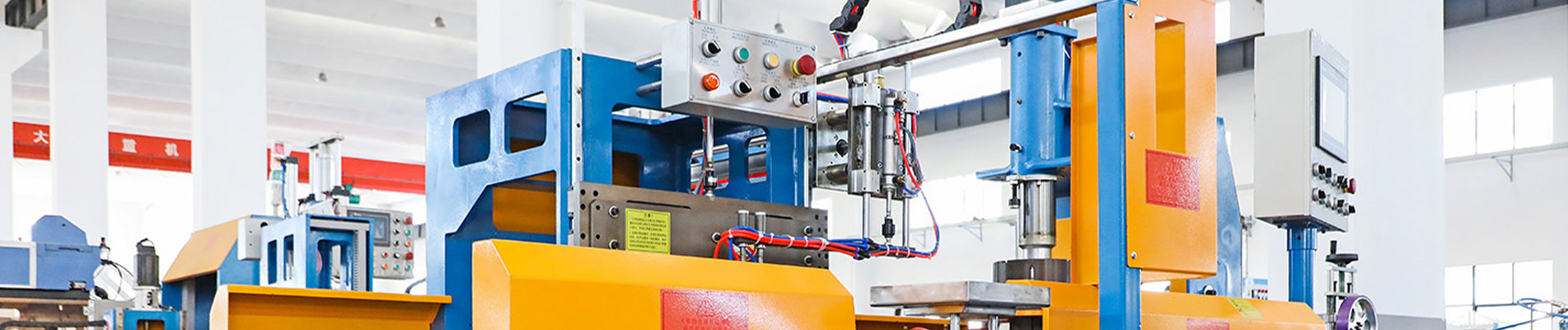

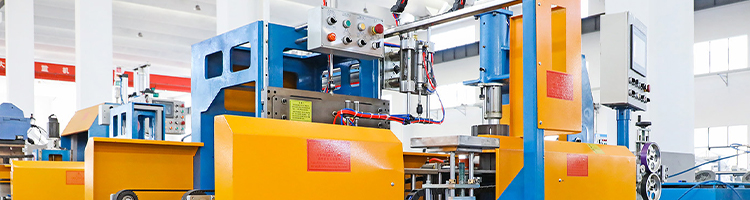

The Low-Smoke Zero-Halogen (LSZH) High-Precision Cable Extruder Machine with Preheater is a specialized production solution tailored for processing LSZH materials—environmentally friendly compounds that emit minimal smoke and zero toxic halogens during combustion. Its integrated material preheater addresses the core challenge of LSZH processing (poor flowability and sensitivity to temperature fluctuations) by pre-conditioning granules to 80℃-100℃ before extrusion . Combined with a dual-stage extrusion system and high-precision die head, this machine achieves insulation thickness tolerance of ±0.02mm—exceeding industry standards for LSZH cables used in public infrastructure.

Equipped with a stainless steel preheater hopper (150kg capacity) with hot-air circulation, maintaining material temperature at 80℃-100℃ with ±2℃ precision—reducing extrusion torque by 25% and eliminating cold spots in melt.

Dual-screw feeding unit (1.5kW power) with enhanced mixing capability ensures uniform dispersion of flame-retardant additives in LSZH compounds, preventing insulation defects like pinholes or uneven hardness.

Main extruder features 33:1 L/D ratio screw (SJ45 model) with low-shear design to protect LSZH’s molecular structure—critical for maintaining flame-retardant performance .

5-zone temperature control (total power 7.5kW) with water cooling for the metering zone (LSZH processing temperature: 170℃-200℃) and a 3-section vacuum cooling tank (length 3000mm) that reduces cable temperature from 200℃ to 40℃ in 12 seconds .

Siemens PLC control system with 7-inch HMI touchscreen, storing 25 LSZH material-specific profiles (e.g., polyolefin-based, elastomer-based) for one-click recall.

Built-in smoke density and halogen content testing interfaces (compatible with third-party detectors) to validate compliance—essential for projects requiring fire safety certifications.

Healthcare Facilities: Produces low-toxicity LSZH wires for medical equipment (e.g., MRI machines) and hospital wiring, complying with NFPA 99 standards.

High-Rise Construction: Extrudes LSZH jacketed cables for building vertical wiring, meeting China’s GB 51348 requirements for fire safety in skyscrapers.

Specialized cable factories producing 100,000km/year of LSZH cables for infrastructure projects, using the preheater to improve material utilization by 12%.

Custom cable production for marine vessels (saltwater-resistant LSZH compounds) requiring strict halogen emission control.

Small-batch manufacturing of high-precision LSZH sensor wires (insulation thickness 0.1mm-0.5mm) for aerospace applications.

Why is a preheater necessary for LSZH processing?

LSZH granules absorb moisture easily (up to 0.3% water content), which causes bubbles in insulation. The preheater removes moisture and softens material, reducing defect rates by 40% .

Can the machine process recycled LSZH materials?

Yes, but recycled content should not exceed 30%; the preheater and dual-screw mixing system help homogenize recycled and virgin materials to maintain performance.

How to maintain the preheater to avoid material caking? Clean the hopper interior every 48 hours and calibrate the temperature sensor monthly—caking occurs if temperature exceeds 120℃ for LSZH compounds.

Does the machine meet European fire safety standards? Yes, it produces cables compliant with EN 50267-2-1 (LSZH requirements) and EN 60332-1-2 (flame spread), with test reports available upon request.

The Low-Smoke Zero-Halogen (LSZH) High-Precision Cable Extruder Machine with Preheater is a specialized production solution tailored for processing LSZH materials—environmentally friendly compounds that emit minimal smoke and zero toxic halogens during combustion. Its integrated material preheater addresses the core challenge of LSZH processing (poor flowability and sensitivity to temperature fluctuations) by pre-conditioning granules to 80℃-100℃ before extrusion . Combined with a dual-stage extrusion system and high-precision die head, this machine achieves insulation thickness tolerance of ±0.02mm—exceeding industry standards for LSZH cables used in public infrastructure.

Equipped with a stainless steel preheater hopper (150kg capacity) with hot-air circulation, maintaining material temperature at 80℃-100℃ with ±2℃ precision—reducing extrusion torque by 25% and eliminating cold spots in melt.

Dual-screw feeding unit (1.5kW power) with enhanced mixing capability ensures uniform dispersion of flame-retardant additives in LSZH compounds, preventing insulation defects like pinholes or uneven hardness.

Main extruder features 33:1 L/D ratio screw (SJ45 model) with low-shear design to protect LSZH’s molecular structure—critical for maintaining flame-retardant performance .

5-zone temperature control (total power 7.5kW) with water cooling for the metering zone (LSZH processing temperature: 170℃-200℃) and a 3-section vacuum cooling tank (length 3000mm) that reduces cable temperature from 200℃ to 40℃ in 12 seconds .

Siemens PLC control system with 7-inch HMI touchscreen, storing 25 LSZH material-specific profiles (e.g., polyolefin-based, elastomer-based) for one-click recall.

Built-in smoke density and halogen content testing interfaces (compatible with third-party detectors) to validate compliance—essential for projects requiring fire safety certifications.

Healthcare Facilities: Produces low-toxicity LSZH wires for medical equipment (e.g., MRI machines) and hospital wiring, complying with NFPA 99 standards.

High-Rise Construction: Extrudes LSZH jacketed cables for building vertical wiring, meeting China’s GB 51348 requirements for fire safety in skyscrapers.

Specialized cable factories producing 100,000km/year of LSZH cables for infrastructure projects, using the preheater to improve material utilization by 12%.

Custom cable production for marine vessels (saltwater-resistant LSZH compounds) requiring strict halogen emission control.

Small-batch manufacturing of high-precision LSZH sensor wires (insulation thickness 0.1mm-0.5mm) for aerospace applications.

Why is a preheater necessary for LSZH processing?

LSZH granules absorb moisture easily (up to 0.3% water content), which causes bubbles in insulation. The preheater removes moisture and softens material, reducing defect rates by 40% .

Can the machine process recycled LSZH materials?

Yes, but recycled content should not exceed 30%; the preheater and dual-screw mixing system help homogenize recycled and virgin materials to maintain performance.

How to maintain the preheater to avoid material caking? Clean the hopper interior every 48 hours and calibrate the temperature sensor monthly—caking occurs if temperature exceeds 120℃ for LSZH compounds.

Does the machine meet European fire safety standards? Yes, it produces cables compliant with EN 50267-2-1 (LSZH requirements) and EN 60332-1-2 (flame spread), with test reports available upon request.