close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

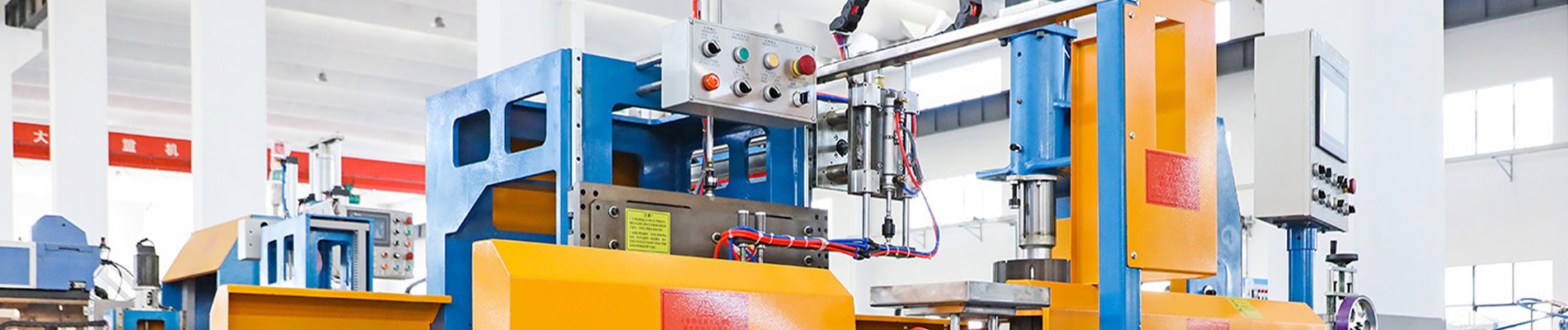

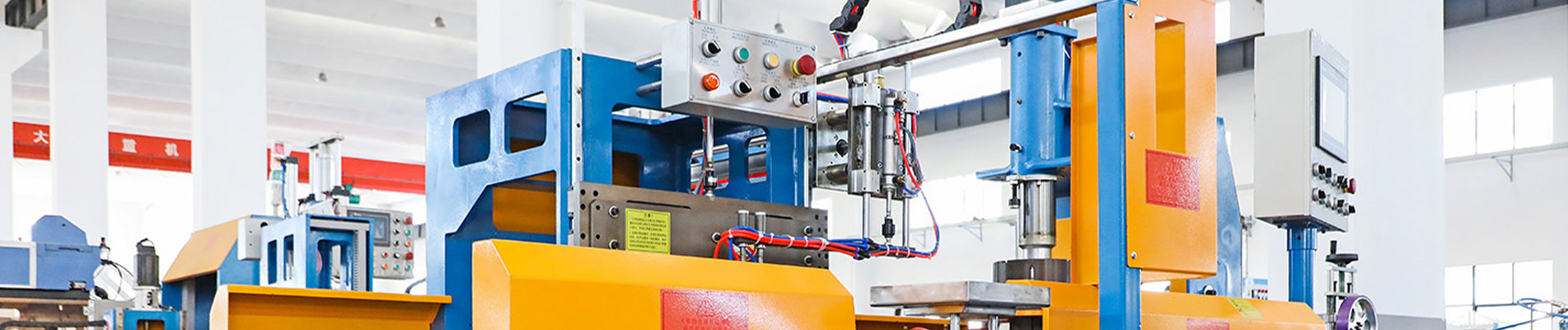

The High-Speed Electrical Wrapping Aluminum Coil Wrapping Machine is a professional packaging equipment tailored for the efficient, damage-free wrapping of aluminum coils and similar cylindrical metal products. It integrates advanced PLC programmable control technology and high-performance drive components to replace labor-intensive manual wrapping, significantly improving packaging efficiency while ensuring uniform tension and consistent wrapping quality across every coil. This machine is designed to adapt to diverse aluminum coil specifications, making it an indispensable tool for aluminum processing plants, metal product distributors, and logistics companies that prioritize packaging speed, product protection, and workflow optimization.

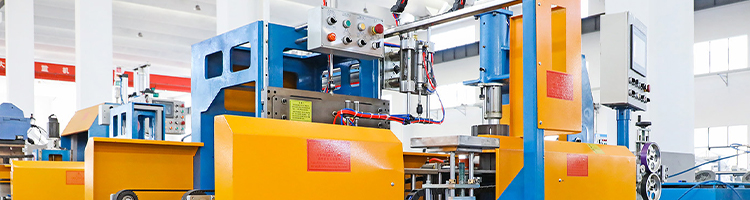

Equipped with a PLC programmable controller and a 7-inch color HMI touch screen, enabling operators to set wrapping parameters (such as speed, tension, and number of layers) with one click and store up to 20 sets of operation templates for quick recall.

Automatic tape cutting and film breaking detection functions reduce manual intervention; the machine will trigger an audible and visual alarm if the packaging material is exhausted, minimizing downtime.

Adjustable wrapping ring height (ranging from 200mm to 1500mm) and movable roller supports, compatible with aluminum coils with outer diameters (OD) of 700mm-1500mm and inner diameters (ID) of 508mm or 610mm.

PU-coated wrapping rollers and soft tension control system prevent scratches, dents, or deformation on the aluminum coil surface, ensuring the product’s appearance and performance remain intact.

Supports multiple packaging materials, including stretch film (thickness 0.02mm-0.05mm), VCI anti-rust paper, and knit tape (width 80mm-100mm), meeting different storage and transportation needs.

Boasts a maximum wrapping ring rotation speed of 80 r/min, 30% faster than standard coil wrapping machines (average 50-60 r/min), enabling it to handle up to 15 coils per hour (based on 1000mm OD coils).

Adopts a heavy-duty cast iron frame and precision gear transmission system, ensuring stable operation even under long-term high-load conditions; the machine’s noise level is controlled below 75dB, creating a comfortable working environment.

Parameter | Specification |

Applicable Coil OD | 700mm - 1500mm |

Applicable Coil ID | 508mm / 610mm |

Applicable Coil Width | 20mm - 300mm |

Maximum Coil Weight | 2000kg |

Wrapping Roller Speed | 5m/min - 8m/min |

Wrapping Ring Speed | 10r/min - 80r/min (adjustable) |

Power Supply | AC 380V 50Hz (3-phase) |

Total Power Consumption | 4.0kW |

Air Pressure Requirement | 6kgf/cm² - 8kgf/cm² |

Machine Dimension (L×W×H) | 2800mm × 1800mm × 2200mm |

Machine Weight | 1800kg |

Aluminum Processing Industry: Used for wrapping finished aluminum coils (such as 1050, 3003, and 5052 series) before storage or shipment, preventing oxidation and scratches.

Automotive & Construction Sectors: Packages aluminum coils used for auto parts (e.g., body panels) and construction materials (e.g., curtain walls), ensuring product quality during transportation.

Logistics & Distribution: Provides moisture-proof, dust-proof, and anti-collision packaging for aluminum coils in long-distance sea or land transportation, reducing cargo damage rates.

High-volume aluminum coil production lines requiring continuous, automated packaging.

Warehouses that need to stack wrapped coils to save storage space (the machine’s tight wrapping ensures stable stacking).

Custom packaging for special aluminum coils (e.g., thin-gauge coils or anodized coils) that require extra surface protection.

How long does it take to set up the machine for a new coil specification?

For operators familiar with the machine, setup (including adjusting roller positions and wrapping parameters) takes 20-30 minutes; new operators can master the process within 1-2 hours with training.

Can the machine adjust wrapping tension automatically?

Yes, the built-in tension sensor detects the coil’s surface pressure in real time and adjusts the wrapping tension (ranging from 5N to 50N) automatically, avoiding over-tightening or loose wrapping.

What is the recommended maintenance cycle for the machine?

Routine maintenance (cleaning rollers, checking gear lubrication) should be done weekly; major maintenance (replacing belts, calibrating sensors) is recommended every 6 months to ensure long-term performance.

Is the machine compatible with existing aluminum coil production lines?

Yes, the machine has a modular design and can be connected to conveyors or coil lifting equipment in most production lines; the manufacturer provides on-site installation and debugging services to ensure seamless integration.

The High-Speed Electrical Wrapping Aluminum Coil Wrapping Machine is a professional packaging equipment tailored for the efficient, damage-free wrapping of aluminum coils and similar cylindrical metal products. It integrates advanced PLC programmable control technology and high-performance drive components to replace labor-intensive manual wrapping, significantly improving packaging efficiency while ensuring uniform tension and consistent wrapping quality across every coil. This machine is designed to adapt to diverse aluminum coil specifications, making it an indispensable tool for aluminum processing plants, metal product distributors, and logistics companies that prioritize packaging speed, product protection, and workflow optimization.

Equipped with a PLC programmable controller and a 7-inch color HMI touch screen, enabling operators to set wrapping parameters (such as speed, tension, and number of layers) with one click and store up to 20 sets of operation templates for quick recall.

Automatic tape cutting and film breaking detection functions reduce manual intervention; the machine will trigger an audible and visual alarm if the packaging material is exhausted, minimizing downtime.

Adjustable wrapping ring height (ranging from 200mm to 1500mm) and movable roller supports, compatible with aluminum coils with outer diameters (OD) of 700mm-1500mm and inner diameters (ID) of 508mm or 610mm.

PU-coated wrapping rollers and soft tension control system prevent scratches, dents, or deformation on the aluminum coil surface, ensuring the product’s appearance and performance remain intact.

Supports multiple packaging materials, including stretch film (thickness 0.02mm-0.05mm), VCI anti-rust paper, and knit tape (width 80mm-100mm), meeting different storage and transportation needs.

Boasts a maximum wrapping ring rotation speed of 80 r/min, 30% faster than standard coil wrapping machines (average 50-60 r/min), enabling it to handle up to 15 coils per hour (based on 1000mm OD coils).

Adopts a heavy-duty cast iron frame and precision gear transmission system, ensuring stable operation even under long-term high-load conditions; the machine’s noise level is controlled below 75dB, creating a comfortable working environment.

Parameter | Specification |

Applicable Coil OD | 700mm - 1500mm |

Applicable Coil ID | 508mm / 610mm |

Applicable Coil Width | 20mm - 300mm |

Maximum Coil Weight | 2000kg |

Wrapping Roller Speed | 5m/min - 8m/min |

Wrapping Ring Speed | 10r/min - 80r/min (adjustable) |

Power Supply | AC 380V 50Hz (3-phase) |

Total Power Consumption | 4.0kW |

Air Pressure Requirement | 6kgf/cm² - 8kgf/cm² |

Machine Dimension (L×W×H) | 2800mm × 1800mm × 2200mm |

Machine Weight | 1800kg |

Aluminum Processing Industry: Used for wrapping finished aluminum coils (such as 1050, 3003, and 5052 series) before storage or shipment, preventing oxidation and scratches.

Automotive & Construction Sectors: Packages aluminum coils used for auto parts (e.g., body panels) and construction materials (e.g., curtain walls), ensuring product quality during transportation.

Logistics & Distribution: Provides moisture-proof, dust-proof, and anti-collision packaging for aluminum coils in long-distance sea or land transportation, reducing cargo damage rates.

High-volume aluminum coil production lines requiring continuous, automated packaging.

Warehouses that need to stack wrapped coils to save storage space (the machine’s tight wrapping ensures stable stacking).

Custom packaging for special aluminum coils (e.g., thin-gauge coils or anodized coils) that require extra surface protection.

How long does it take to set up the machine for a new coil specification?

For operators familiar with the machine, setup (including adjusting roller positions and wrapping parameters) takes 20-30 minutes; new operators can master the process within 1-2 hours with training.

Can the machine adjust wrapping tension automatically?

Yes, the built-in tension sensor detects the coil’s surface pressure in real time and adjusts the wrapping tension (ranging from 5N to 50N) automatically, avoiding over-tightening or loose wrapping.

What is the recommended maintenance cycle for the machine?

Routine maintenance (cleaning rollers, checking gear lubrication) should be done weekly; major maintenance (replacing belts, calibrating sensors) is recommended every 6 months to ensure long-term performance.

Is the machine compatible with existing aluminum coil production lines?

Yes, the machine has a modular design and can be connected to conveyors or coil lifting equipment in most production lines; the manufacturer provides on-site installation and debugging services to ensure seamless integration.