close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

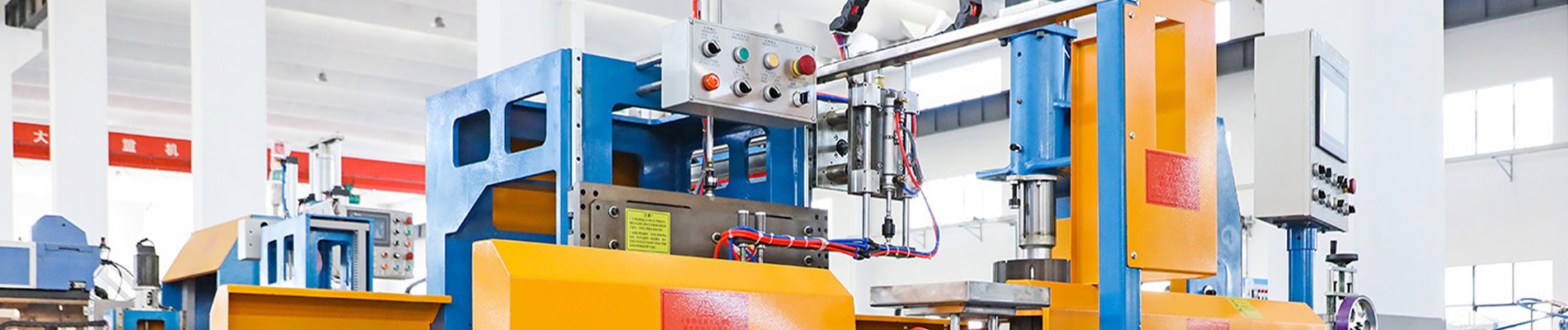

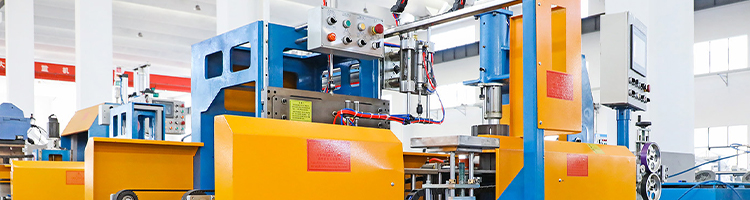

The Full-Automatic High-Performance PE PVC Cable Extruder Machine is an integrated production system engineered for continuous, high-precision extrusion of PE (polyethylene) and PVC (polyvinyl chloride) insulation layers and protective jackets for wires and cables. Unlike semi-automatic counterparts, it integrates automatic pay-off, precision extrusion, intelligent cooling, and synchronized haul-off-take-up units, eliminating manual intervention across the entire production process . Powered by a high-torque gearbox motor and PLC control system (Simatic Multi Panel), this machine delivers extrusion speeds up to 120kg/h for PVC materials—50% faster than standard extruders—while maintaining insulation thickness tolerance within ±0.03mm. It has become a cornerstone for cable manufacturers targeting mass production of power cables, communication wires, and automotive harnesses, aligning with global standards like IEC 60228 and GB/T 12706.

Equipped with an automatic vacuum feeder (1.5kW power) that conveys PE/PVC granules (2mm-5mm diameter) from storage silos to the extruder hopper, with a loading capacity of 150kg/h and material level sensors to prevent dry running .

Integrates synchronized pay-off (max conductor diameter 15mm) and 12-claw traction machine with variable speed (5m/min-30m/min), ensuring consistent tension control to avoid conductor stretching or insulation cracking .

Automatic cutting unit (saw-type or 屑 - free optional) triggers via length encoder, achieving cutting precision within ±2mm for finished cables up to 300m in coil length.

Features a 30:1 L/D ratio screw (SJ65 model) made of 38CrMoAl alloy steel (nitrided surface, HRC 60-65) with special spiral groove design for enhanced material plasticization—reducing melt temperature variation to ±1℃ .

6-zone aluminum casting heating system (total power 16kW) paired with blower cooling for the barrel and water cooling for the screw core, monitored by digital PID controllers to avoid material degradation (PVC processing temperature: 160℃-190℃; PE: 180℃-230℃) .

H-shaped welded steel frame reduces machine vibration by 40% during high-speed operation, while the enclosed gearbox (noise ≤70dB) ensures long-term reliability with 20,000-hour service life .

Inverter-driven main motor (11kW-18.5kW) adjusts speed proportionally to production demand, cutting energy consumption by 18% compared to fixed-speed extruders—critical for 24/7 manufacturing environments.

Power Cable Manufacturing: Produces 0.6/1kV PVC-insulated power cables and medium-voltage PE-insulated cables for residential grids and industrial distribution networks.

Automotive Wiring Harnesses: Extrudes thin-wall PVC insulation (0.2mm-1.0mm) for automotive signal wires, complying with ISO 6722 standards for temperature resistance (-40℃ to 105℃).

Communication Cable Production: Processes PE-jacketed Cat6/Cat6a network cables with stable impedance (100±15Ω) for data center infrastructure.

Large-scale cable factories with 500,000km/year production capacity, leveraging full automation to reduce labor costs by 60%.

Contract manufacturing for electrical brands requiring frequent material switches—quick-change die heads (30-minute replacement) support flexible production.

High-volume PVC wire production for construction projects, using the machine’s high extrusion speed to meet tight delivery deadlines.

How long does it take to switch from PE to PVC processing?

With the quick-change barrel liner and die head, material changeover takes 45-60 minutes, including screw cleaning with dedicated purging compounds .

What is the maximum continuous production time?

The machine supports 24/7 operation; scheduled maintenance (lubrication, filter replacement) is only required every 72 hours to avoid unplanned downtime.

How often should the extrusion filter be replaced?

For PVC materials, replace the 120-mesh filter every 8 hours; for PE, extend to 12 hours—clogged filters cause pressure spikes and uneven insulation .

Can the machine detect insulation defects in real time?

Yes, optional online thickness gauges (laser-based) monitor insulation diameter continuously, triggering automatic speed adjustment or alarms for deviations exceeding ±0.03mm .

| Height H (mm) | Outside Diameter O.D ( mm ) | Inside Diameter I D (mm) | Wire/Cable Diameter (mm) | Average output ( 100M / Coil ) |

CP1040 | 50-100 | Ø180-Ø400 | Ø120-Ø200 | Ø3 - Ø 8 | 2Coils/Min. |

CP1860 | 70-150 | Ø280-Ø600 | Ø180-Ø250 | Ø5 - Ø 15 | 1Coils/Min. |

The Full-Automatic High-Performance PE PVC Cable Extruder Machine is an integrated production system engineered for continuous, high-precision extrusion of PE (polyethylene) and PVC (polyvinyl chloride) insulation layers and protective jackets for wires and cables. Unlike semi-automatic counterparts, it integrates automatic pay-off, precision extrusion, intelligent cooling, and synchronized haul-off-take-up units, eliminating manual intervention across the entire production process . Powered by a high-torque gearbox motor and PLC control system (Simatic Multi Panel), this machine delivers extrusion speeds up to 120kg/h for PVC materials—50% faster than standard extruders—while maintaining insulation thickness tolerance within ±0.03mm. It has become a cornerstone for cable manufacturers targeting mass production of power cables, communication wires, and automotive harnesses, aligning with global standards like IEC 60228 and GB/T 12706.

Equipped with an automatic vacuum feeder (1.5kW power) that conveys PE/PVC granules (2mm-5mm diameter) from storage silos to the extruder hopper, with a loading capacity of 150kg/h and material level sensors to prevent dry running .

Integrates synchronized pay-off (max conductor diameter 15mm) and 12-claw traction machine with variable speed (5m/min-30m/min), ensuring consistent tension control to avoid conductor stretching or insulation cracking .

Automatic cutting unit (saw-type or 屑 - free optional) triggers via length encoder, achieving cutting precision within ±2mm for finished cables up to 300m in coil length.

Features a 30:1 L/D ratio screw (SJ65 model) made of 38CrMoAl alloy steel (nitrided surface, HRC 60-65) with special spiral groove design for enhanced material plasticization—reducing melt temperature variation to ±1℃ .

6-zone aluminum casting heating system (total power 16kW) paired with blower cooling for the barrel and water cooling for the screw core, monitored by digital PID controllers to avoid material degradation (PVC processing temperature: 160℃-190℃; PE: 180℃-230℃) .

H-shaped welded steel frame reduces machine vibration by 40% during high-speed operation, while the enclosed gearbox (noise ≤70dB) ensures long-term reliability with 20,000-hour service life .

Inverter-driven main motor (11kW-18.5kW) adjusts speed proportionally to production demand, cutting energy consumption by 18% compared to fixed-speed extruders—critical for 24/7 manufacturing environments.

Power Cable Manufacturing: Produces 0.6/1kV PVC-insulated power cables and medium-voltage PE-insulated cables for residential grids and industrial distribution networks.

Automotive Wiring Harnesses: Extrudes thin-wall PVC insulation (0.2mm-1.0mm) for automotive signal wires, complying with ISO 6722 standards for temperature resistance (-40℃ to 105℃).

Communication Cable Production: Processes PE-jacketed Cat6/Cat6a network cables with stable impedance (100±15Ω) for data center infrastructure.

Large-scale cable factories with 500,000km/year production capacity, leveraging full automation to reduce labor costs by 60%.

Contract manufacturing for electrical brands requiring frequent material switches—quick-change die heads (30-minute replacement) support flexible production.

High-volume PVC wire production for construction projects, using the machine’s high extrusion speed to meet tight delivery deadlines.

How long does it take to switch from PE to PVC processing?

With the quick-change barrel liner and die head, material changeover takes 45-60 minutes, including screw cleaning with dedicated purging compounds .

What is the maximum continuous production time?

The machine supports 24/7 operation; scheduled maintenance (lubrication, filter replacement) is only required every 72 hours to avoid unplanned downtime.

How often should the extrusion filter be replaced?

For PVC materials, replace the 120-mesh filter every 8 hours; for PE, extend to 12 hours—clogged filters cause pressure spikes and uneven insulation .

Can the machine detect insulation defects in real time?

Yes, optional online thickness gauges (laser-based) monitor insulation diameter continuously, triggering automatic speed adjustment or alarms for deviations exceeding ±0.03mm .

| Height H (mm) | Outside Diameter O.D ( mm ) | Inside Diameter I D (mm) | Wire/Cable Diameter (mm) | Average output ( 100M / Coil ) |

CP1040 | 50-100 | Ø180-Ø400 | Ø120-Ø200 | Ø3 - Ø 8 | 2Coils/Min. |

CP1860 | 70-150 | Ø280-Ø600 | Ø180-Ø250 | Ø5 - Ø 15 | 1Coils/Min. |