close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

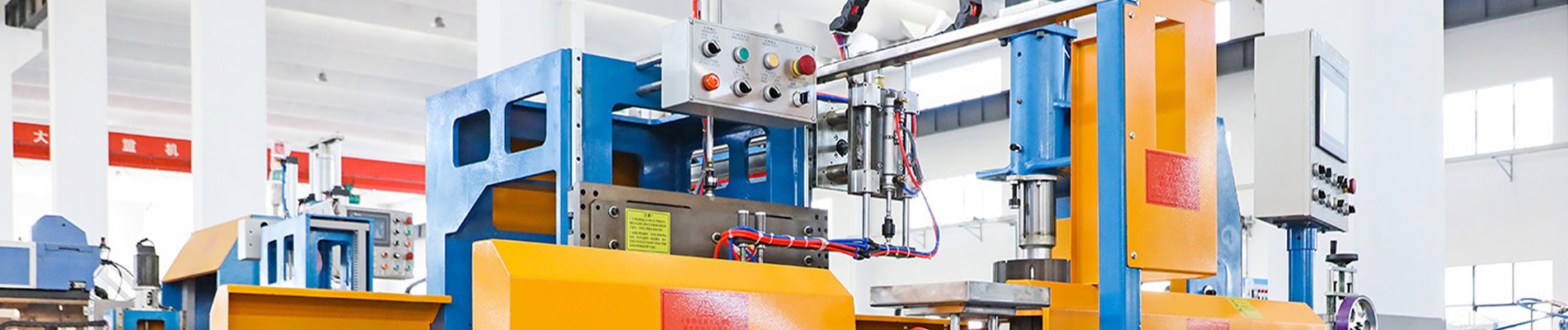

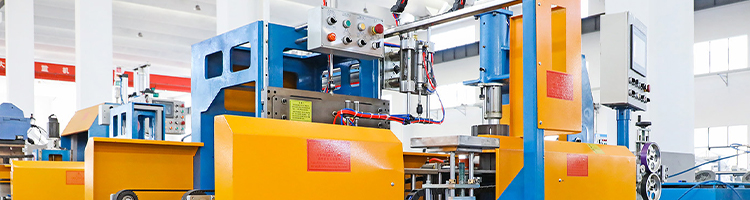

The Automatic Single-Screw PVC PP Wire Coil Wrapping Machine is a specialized packaging equipment designed for wrapping PVC (polyvinyl chloride) and PP (polypropylene) wire coils with stretch film or anti-rust paper. It integrates a single-screw drive system, an automatic film feeding mechanism, and a turntable for coil rotation, achieving fully automated wrapping without manual intervention. This machine solves the problems of loose wrapping, uneven film coverage, and high labor costs in manual wrapping of wire coils, ensuring that the coils are protected from dust, moisture, and scratches during storage and transportation. It is a key equipment in wire and cable distribution centers, hardware stores, and electrical product manufacturers, supporting coil sizes from small (50mm OD) to large (800mm OD).

Adopts a PLC control system and a turntable driven by a 0.75kW geared motor, enabling automatic coil loading (via conveyor), turntable rotation (5r/min-15r/min), film feeding, and film cutting; the entire wrapping cycle for a 300mm OD coil takes 20-30 seconds, improving efficiency by 300% compared to manual wrapping.

Equipped with an automatic film tension control system that adjusts film tension (0.5kg-3kg) according to coil size and film thickness, ensuring tight wrapping without damaging the wire insulation.

Features a single-screw film feeding mechanism (screw diameter 20mm) with a film width range of 50mm-150mm, compatible with stretch film (thickness 0.015mm-0.03mm) and VCI anti-rust paper (thickness 0.1mm-0.2mm); the screw’s variable speed design (10r/min-50r/min) controls film feeding speed to match turntable speed.

Quick-change film rolls: the film holder has a snap-on design that allows replacing film rolls in 30-60 seconds, reducing downtime during material changes.

Built-in safety features: a light curtain sensor that stops the turntable if hands or objects enter the wrapping area, and an emergency stop button on the control panel; the machine’s electrical system complies with CE safety standards.

Compact structure (dimension 1200mm × 1000mm × 1800mm) that occupies only 1.2 square meters of floor space, suitable for small workshops or distribution centers with limited space.

Wire Distribution Centers: Wraps PVC/PP wire coils (e.g., 1.5mm²-6mm² power wires) for wholesale to hardware stores, electrical contractors, and construction companies.

Household Electrical Appliance Manufacturing: Packages small wire coils (e.g., 50mm-100mm OD) for power cords of refrigerators, washing machines, and air conditioners, ensuring clean and damage-free cords during assembly.

Hardware & Retail: Wraps PP wire coils (e.g., binding wires, garden wires) into small, easy-to-carry coils for retail sales, with clear labeling space on the wrapped film.

High-volume wire coil packaging lines (e.g., 1000-2000 coils per day) in wire distribution centers, using stretch film for cost-effective protection.

Packaging of outdoor-use PVC wires (e.g., garden wires) with VCI anti-rust paper to prevent moisture and corrosion during outdoor storage.

Small workshops producing custom wire coils (e.g., 300mm-500mm OD) that require consistent wrapping quality for brand image maintenance.

How many coils can the machine wrap per hour?

For 300mm OD coils (the most common size), the machine can wrap 120-180 coils per hour (based on a 20-30 second cycle); for smaller coils (100mm OD), the capacity increases to 240-300 coils per hour.

Can the machine wrap coils with irregular shapes?

Yes, the machine’s adjustable turntable and soft tension control system can handle slightly irregular coils (e.g., oval or slightly flattened coils); for highly irregular shapes, a custom coil holder (provided by the manufacturer) is required.

What is the maintenance cost of the machine?

Routine maintenance (cleaning the turntable, lubricating the screw) costs less than $50 per month; the single-screw and turntable motor have a service life of over 5 years, and replacement parts are affordable and readily available.

How much film does the machine consume per coil?

For a 300mm OD coil (height 100mm), the machine uses 0.5m-0.8m of 100mm wide stretch film (thickness 0.02mm), with a film cost of 0.05-0.10 per coil, significantly lower than manual wrapping (which wastes 20%-30% more film).

| Height H (mm) | Outside Diameter O.D ( mm ) | Inside Diameter I D (mm) | Wire/Cable Diameter (mm) | Average output ( 100M / Coil ) |

CP1040 | 50-100 | Ø180-Ø400 | Ø120-Ø200 | Ø3 - Ø 8 | 2Coils/Min. |

CP1860 | 70-150 | Ø280-Ø600 | Ø180-Ø250 | Ø5 - Ø 15 | 1Coils/Min. |

The Automatic Single-Screw PVC PP Wire Coil Wrapping Machine is a specialized packaging equipment designed for wrapping PVC (polyvinyl chloride) and PP (polypropylene) wire coils with stretch film or anti-rust paper. It integrates a single-screw drive system, an automatic film feeding mechanism, and a turntable for coil rotation, achieving fully automated wrapping without manual intervention. This machine solves the problems of loose wrapping, uneven film coverage, and high labor costs in manual wrapping of wire coils, ensuring that the coils are protected from dust, moisture, and scratches during storage and transportation. It is a key equipment in wire and cable distribution centers, hardware stores, and electrical product manufacturers, supporting coil sizes from small (50mm OD) to large (800mm OD).

Adopts a PLC control system and a turntable driven by a 0.75kW geared motor, enabling automatic coil loading (via conveyor), turntable rotation (5r/min-15r/min), film feeding, and film cutting; the entire wrapping cycle for a 300mm OD coil takes 20-30 seconds, improving efficiency by 300% compared to manual wrapping.

Equipped with an automatic film tension control system that adjusts film tension (0.5kg-3kg) according to coil size and film thickness, ensuring tight wrapping without damaging the wire insulation.

Features a single-screw film feeding mechanism (screw diameter 20mm) with a film width range of 50mm-150mm, compatible with stretch film (thickness 0.015mm-0.03mm) and VCI anti-rust paper (thickness 0.1mm-0.2mm); the screw’s variable speed design (10r/min-50r/min) controls film feeding speed to match turntable speed.

Quick-change film rolls: the film holder has a snap-on design that allows replacing film rolls in 30-60 seconds, reducing downtime during material changes.

Built-in safety features: a light curtain sensor that stops the turntable if hands or objects enter the wrapping area, and an emergency stop button on the control panel; the machine’s electrical system complies with CE safety standards.

Compact structure (dimension 1200mm × 1000mm × 1800mm) that occupies only 1.2 square meters of floor space, suitable for small workshops or distribution centers with limited space.

Wire Distribution Centers: Wraps PVC/PP wire coils (e.g., 1.5mm²-6mm² power wires) for wholesale to hardware stores, electrical contractors, and construction companies.

Household Electrical Appliance Manufacturing: Packages small wire coils (e.g., 50mm-100mm OD) for power cords of refrigerators, washing machines, and air conditioners, ensuring clean and damage-free cords during assembly.

Hardware & Retail: Wraps PP wire coils (e.g., binding wires, garden wires) into small, easy-to-carry coils for retail sales, with clear labeling space on the wrapped film.

High-volume wire coil packaging lines (e.g., 1000-2000 coils per day) in wire distribution centers, using stretch film for cost-effective protection.

Packaging of outdoor-use PVC wires (e.g., garden wires) with VCI anti-rust paper to prevent moisture and corrosion during outdoor storage.

Small workshops producing custom wire coils (e.g., 300mm-500mm OD) that require consistent wrapping quality for brand image maintenance.

How many coils can the machine wrap per hour?

For 300mm OD coils (the most common size), the machine can wrap 120-180 coils per hour (based on a 20-30 second cycle); for smaller coils (100mm OD), the capacity increases to 240-300 coils per hour.

Can the machine wrap coils with irregular shapes?

Yes, the machine’s adjustable turntable and soft tension control system can handle slightly irregular coils (e.g., oval or slightly flattened coils); for highly irregular shapes, a custom coil holder (provided by the manufacturer) is required.

What is the maintenance cost of the machine?

Routine maintenance (cleaning the turntable, lubricating the screw) costs less than $50 per month; the single-screw and turntable motor have a service life of over 5 years, and replacement parts are affordable and readily available.

How much film does the machine consume per coil?

For a 300mm OD coil (height 100mm), the machine uses 0.5m-0.8m of 100mm wide stretch film (thickness 0.02mm), with a film cost of 0.05-0.10 per coil, significantly lower than manual wrapping (which wastes 20%-30% more film).

| Height H (mm) | Outside Diameter O.D ( mm ) | Inside Diameter I D (mm) | Wire/Cable Diameter (mm) | Average output ( 100M / Coil ) |

CP1040 | 50-100 | Ø180-Ø400 | Ø120-Ø200 | Ø3 - Ø 8 | 2Coils/Min. |

CP1860 | 70-150 | Ø280-Ø600 | Ø180-Ø250 | Ø5 - Ø 15 | 1Coils/Min. |