close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

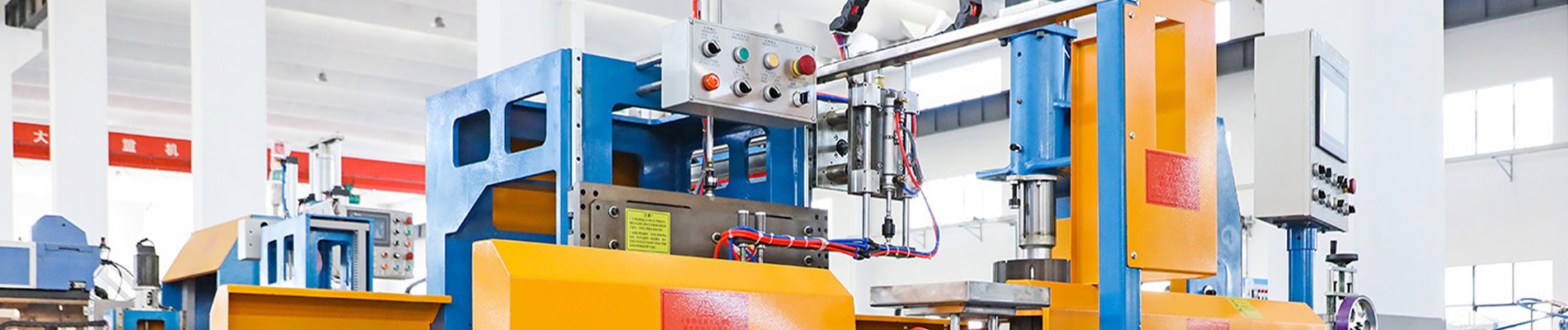

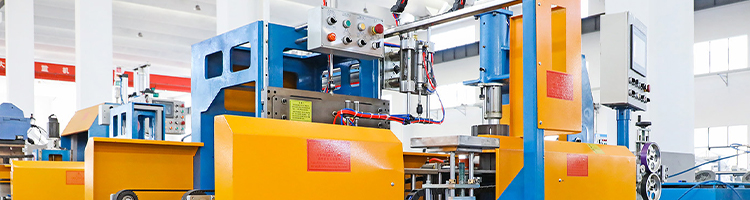

The Electrical XLPE PE Cable Extruder Machine with Water Tank is an integrated production equipment designed for the extrusion and cooling of XLPE (cross-linked polyethylene) and PE (polyethylene) insulated cables. It combines a high-precision single-screw extruder, a temperature-controlled electrical heating system, and a multi-section water tank to achieve continuous, high-quality cable insulation processing. This machine addresses the challenges of uneven insulation thickness and slow cooling in traditional cable production, ensuring stable electrical performance and mechanical strength of the finished cables. It is widely used in power cable, communication cable, and automotive wire manufacturing industries, meeting the strict standards of IEC, GB, and ANSI for cable insulation.

Adopts a 30:1 L/D (length-to-diameter ratio) single screw made of 38CrMoAl alloy steel (after nitriding treatment), ensuring strong plasticizing ability and uniform melting of XLPE/PE materials; the screw’s surface hardness reaches HRC 60-65, with a service life of over 5 years.

Equipped with a PLC-based temperature control system that monitors 5 heating zones (feed zone, compression zone, metering zone, die head, and adapter) with an accuracy of ±1℃, avoiding material degradation caused by overheating or insufficient heating.

Integrates a 3-section stainless steel water tank (total length 3000mm) with independent temperature control (5℃-40℃ adjustable) and water circulation system; the first section uses spray cooling, the second and third sections use immersion cooling, ensuring rapid and uniform cooling of the insulated cable, reducing internal stress.

Equipped with a cable guide device and a tension control roller in the water tank, preventing cable deviation during cooling and ensuring consistent insulation thickness (tolerance ≤ ±0.05mm).

Uses inverter-controlled extruder motors (power 11kW-15kW) that adjust speed according to production needs, reducing energy consumption by 15%-20% compared to fixed-speed motors.

Built-in safety protection functions: emergency stop buttons, over-temperature alarms, and motor overload protection; the machine’s electrical system complies with IP54 protection standards, suitable for industrial workshop environments with dust and moisture.

Parameter | Specification |

Applicable Materials | XLPE, PE (granule diameter 2mm-5mm) |

Screw L/D Ratio | 30:1 |

Screw Diameter | 65mm / 75mm (optional) |

Extrusion Speed | 5m/min - 20m/min |

Insulation Thickness | 0.5mm - 5.0mm |

Cable Conductor Diameter | 0.8mm - 12mm |

Heating Power | 18kW (5 heating zones) |

Water Tank Length | 3000mm (3 sections) |

Water Temperature Range | 5℃ - 40℃ (adjustable) |

Power Supply | AC 380V 50Hz (3-phase) |

Machine Dimension (L×W×H) | 6500mm × 1200mm × 1800mm |

Machine Weight | 2200kg |

Power Cable Manufacturing: Produces XLPE-insulated power cables (1kV-35kV) for residential, industrial, and utility power distribution networks.

Communication Cable Industry: Processes PE-insulated communication cables (e.g., Cat5e, Cat6) and coaxial cables, ensuring stable signal transmission.

Automotive & Marine Wire Sector: Manufactures PE-insulated wires for automotive wiring harnesses and marine cables (with corrosion-resistant insulation), meeting automotive industry standards (e.g., ISO 6722) and marine standards (e.g., IEC 60092).

Continuous production lines for medium and low-voltage power cables requiring high insulation performance.

Custom cable production for special environments (e.g., high-temperature or humid areas) using XLPE materials with excellent heat resistance.

Small-batch production of communication cables with frequent material changes (the machine’s quick-change die head reduces material replacement time to 30-40 minutes).

What is the minimum batch size for XLPE material processing?

The machine can handle batches as small as 50kg of XLPE granules, making it suitable for both large-scale production and small-batch customization.

How to clean the extruder when switching from PE to XLPE?

The manufacturer provides a dedicated cleaning agent; the cleaning process takes 20-25 minutes, and the machine’s split-type barrel design allows easy access to the screw for thorough cleaning.

How often should the water tank’s filter be replaced?

The water filter should be replaced every 2 weeks to prevent impurities from adhering to the cable surface and affecting insulation quality.

Does the machine support online thickness testing?

Yes, the machine can be equipped with an optional laser thickness gauge that monitors insulation thickness in real time and adjusts the extruder speed automatically to maintain thickness tolerance within ±0.05mm.

The Electrical XLPE PE Cable Extruder Machine with Water Tank is an integrated production equipment designed for the extrusion and cooling of XLPE (cross-linked polyethylene) and PE (polyethylene) insulated cables. It combines a high-precision single-screw extruder, a temperature-controlled electrical heating system, and a multi-section water tank to achieve continuous, high-quality cable insulation processing. This machine addresses the challenges of uneven insulation thickness and slow cooling in traditional cable production, ensuring stable electrical performance and mechanical strength of the finished cables. It is widely used in power cable, communication cable, and automotive wire manufacturing industries, meeting the strict standards of IEC, GB, and ANSI for cable insulation.

Adopts a 30:1 L/D (length-to-diameter ratio) single screw made of 38CrMoAl alloy steel (after nitriding treatment), ensuring strong plasticizing ability and uniform melting of XLPE/PE materials; the screw’s surface hardness reaches HRC 60-65, with a service life of over 5 years.

Equipped with a PLC-based temperature control system that monitors 5 heating zones (feed zone, compression zone, metering zone, die head, and adapter) with an accuracy of ±1℃, avoiding material degradation caused by overheating or insufficient heating.

Integrates a 3-section stainless steel water tank (total length 3000mm) with independent temperature control (5℃-40℃ adjustable) and water circulation system; the first section uses spray cooling, the second and third sections use immersion cooling, ensuring rapid and uniform cooling of the insulated cable, reducing internal stress.

Equipped with a cable guide device and a tension control roller in the water tank, preventing cable deviation during cooling and ensuring consistent insulation thickness (tolerance ≤ ±0.05mm).

Uses inverter-controlled extruder motors (power 11kW-15kW) that adjust speed according to production needs, reducing energy consumption by 15%-20% compared to fixed-speed motors.

Built-in safety protection functions: emergency stop buttons, over-temperature alarms, and motor overload protection; the machine’s electrical system complies with IP54 protection standards, suitable for industrial workshop environments with dust and moisture.

Parameter | Specification |

Applicable Materials | XLPE, PE (granule diameter 2mm-5mm) |

Screw L/D Ratio | 30:1 |

Screw Diameter | 65mm / 75mm (optional) |

Extrusion Speed | 5m/min - 20m/min |

Insulation Thickness | 0.5mm - 5.0mm |

Cable Conductor Diameter | 0.8mm - 12mm |

Heating Power | 18kW (5 heating zones) |

Water Tank Length | 3000mm (3 sections) |

Water Temperature Range | 5℃ - 40℃ (adjustable) |

Power Supply | AC 380V 50Hz (3-phase) |

Machine Dimension (L×W×H) | 6500mm × 1200mm × 1800mm |

Machine Weight | 2200kg |

Power Cable Manufacturing: Produces XLPE-insulated power cables (1kV-35kV) for residential, industrial, and utility power distribution networks.

Communication Cable Industry: Processes PE-insulated communication cables (e.g., Cat5e, Cat6) and coaxial cables, ensuring stable signal transmission.

Automotive & Marine Wire Sector: Manufactures PE-insulated wires for automotive wiring harnesses and marine cables (with corrosion-resistant insulation), meeting automotive industry standards (e.g., ISO 6722) and marine standards (e.g., IEC 60092).

Continuous production lines for medium and low-voltage power cables requiring high insulation performance.

Custom cable production for special environments (e.g., high-temperature or humid areas) using XLPE materials with excellent heat resistance.

Small-batch production of communication cables with frequent material changes (the machine’s quick-change die head reduces material replacement time to 30-40 minutes).

What is the minimum batch size for XLPE material processing?

The machine can handle batches as small as 50kg of XLPE granules, making it suitable for both large-scale production and small-batch customization.

How to clean the extruder when switching from PE to XLPE?

The manufacturer provides a dedicated cleaning agent; the cleaning process takes 20-25 minutes, and the machine’s split-type barrel design allows easy access to the screw for thorough cleaning.

How often should the water tank’s filter be replaced?

The water filter should be replaced every 2 weeks to prevent impurities from adhering to the cable surface and affecting insulation quality.

Does the machine support online thickness testing?

Yes, the machine can be equipped with an optional laser thickness gauge that monitors insulation thickness in real time and adjusts the extruder speed automatically to maintain thickness tolerance within ±0.05mm.