close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

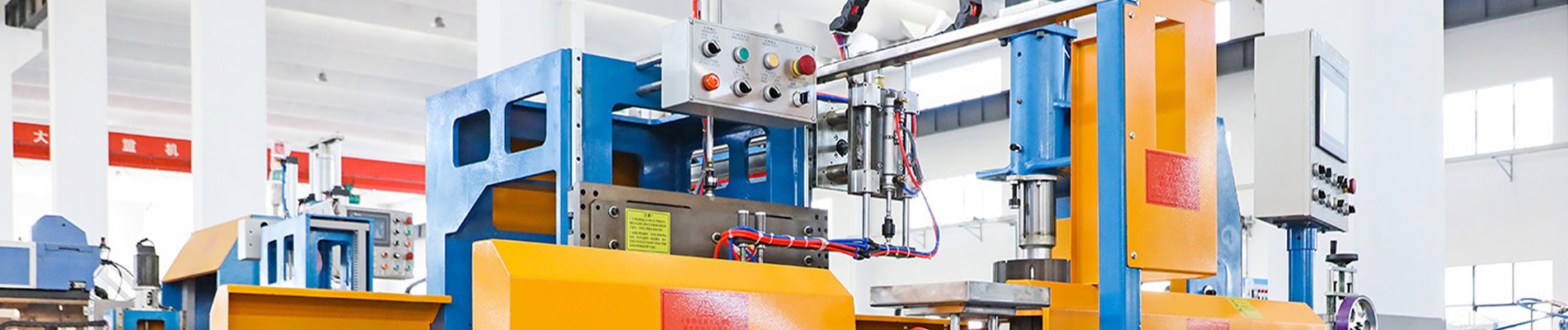

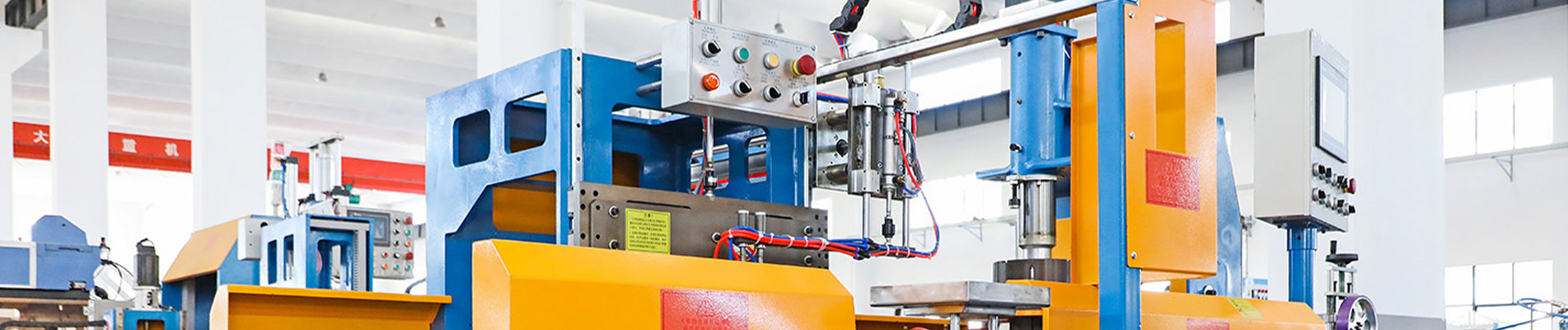

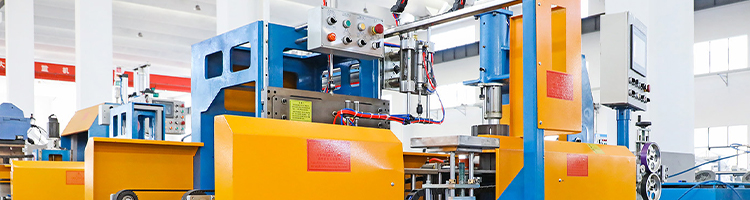

The High-Efficiency PP PVC PE Cable Extruder Machine is a multi-functional production core designed for energy-saving and high-yield extrusion of insulation layers and jackets using PP (polypropylene), PVC (polyvinyl chloride), and PE (polyethylene) materials. Distinguished by its optimized material adaptation and low-energy operation, this machine integrates advanced torque transmission and precision plasticization systems to achieve 15% higher material utilization than conventional extruders . Equipped with a hardened helical gear reducer and intelligent power regulation, it maintains stable extrusion even when switching between PP’s crystalline structure and PVC’s amorphous properties, with a maximum output of 240kg/h for large-caliber cables . It has become the preferred equipment for cable manufacturers focusing on cost control and multi-material production, complying with IEC 60228 and ASTM D2240 standards.

Adopts a 32:1 L/D ratio screw (SJ90 model) with variable pitch design—deep grooves for PP’s high melting flow rate and gradual compression sections for PVC’s heat sensitivity, ensuring uniform plasticization across all three materials.

Equipped with a dual-chamber hopper (200kg capacity) with separate temperature zones: PP preheating at 60℃-80℃, PVC drying at 40℃-50℃, eliminating moisture-related defects like bubbles .

Integrates an ER series helical gear hard tooth surface reducer with carburizing and quenching treatment, reducing operation noise to ≤65dB and extending service life to 30,000 hours while maintaining torque stability .

Siemens S7-1200 PLC system with 10-inch touchscreen, storing 40 material-specific profiles (e.g., PP homopolymer, PE cross-linked) and auto-adjusting screw speed (50-300rpm) based on melt pressure .

Features a hydraulic dual-station screen changer with automatic pressure monitoring, enabling filter replacement in 30 seconds without stopping production—critical for PP’s impurity-sensitive processing .

H-shaped welded steel frame with reinforced vibration damping pads, reducing machine oscillation by 50% during high-speed extrusion of heavy-gauge PE jackets .

Power Cable Manufacturing: Produces 10kV PE-insulated power cables and low-voltage PP-jacketed control cables for industrial distribution networks.

Telecommunication Infrastructure: Extrudes PE-insulated fiber optic cable jackets with stable diameter control for 5G base station connections.

Automotive Wiring: Processes PVC thin-wall insulation (0.3mm-2.0mm) for automotive power cables, complying with ISO 6722 Class B standards.

Medium-sized cable factories with 300,000km/year production capacity, using multi-material compatibility to serve diverse client orders without equipment replacement.

Contract manufacturers handling small-batch custom cables, leveraging quick profile recall to reduce setup time by 40%.

PP cable production lines for renewable energy projects, utilizing high material utilization to lower waste costs by 12%.

The High-Efficiency PP PVC PE Cable Extruder Machine is a multi-functional production core designed for energy-saving and high-yield extrusion of insulation layers and jackets using PP (polypropylene), PVC (polyvinyl chloride), and PE (polyethylene) materials. Distinguished by its optimized material adaptation and low-energy operation, this machine integrates advanced torque transmission and precision plasticization systems to achieve 15% higher material utilization than conventional extruders . Equipped with a hardened helical gear reducer and intelligent power regulation, it maintains stable extrusion even when switching between PP’s crystalline structure and PVC’s amorphous properties, with a maximum output of 240kg/h for large-caliber cables . It has become the preferred equipment for cable manufacturers focusing on cost control and multi-material production, complying with IEC 60228 and ASTM D2240 standards.

Adopts a 32:1 L/D ratio screw (SJ90 model) with variable pitch design—deep grooves for PP’s high melting flow rate and gradual compression sections for PVC’s heat sensitivity, ensuring uniform plasticization across all three materials.

Equipped with a dual-chamber hopper (200kg capacity) with separate temperature zones: PP preheating at 60℃-80℃, PVC drying at 40℃-50℃, eliminating moisture-related defects like bubbles .

Integrates an ER series helical gear hard tooth surface reducer with carburizing and quenching treatment, reducing operation noise to ≤65dB and extending service life to 30,000 hours while maintaining torque stability .

Siemens S7-1200 PLC system with 10-inch touchscreen, storing 40 material-specific profiles (e.g., PP homopolymer, PE cross-linked) and auto-adjusting screw speed (50-300rpm) based on melt pressure .

Features a hydraulic dual-station screen changer with automatic pressure monitoring, enabling filter replacement in 30 seconds without stopping production—critical for PP’s impurity-sensitive processing .

H-shaped welded steel frame with reinforced vibration damping pads, reducing machine oscillation by 50% during high-speed extrusion of heavy-gauge PE jackets .

Power Cable Manufacturing: Produces 10kV PE-insulated power cables and low-voltage PP-jacketed control cables for industrial distribution networks.

Telecommunication Infrastructure: Extrudes PE-insulated fiber optic cable jackets with stable diameter control for 5G base station connections.

Automotive Wiring: Processes PVC thin-wall insulation (0.3mm-2.0mm) for automotive power cables, complying with ISO 6722 Class B standards.

Medium-sized cable factories with 300,000km/year production capacity, using multi-material compatibility to serve diverse client orders without equipment replacement.

Contract manufacturers handling small-batch custom cables, leveraging quick profile recall to reduce setup time by 40%.

PP cable production lines for renewable energy projects, utilizing high material utilization to lower waste costs by 12%.