close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

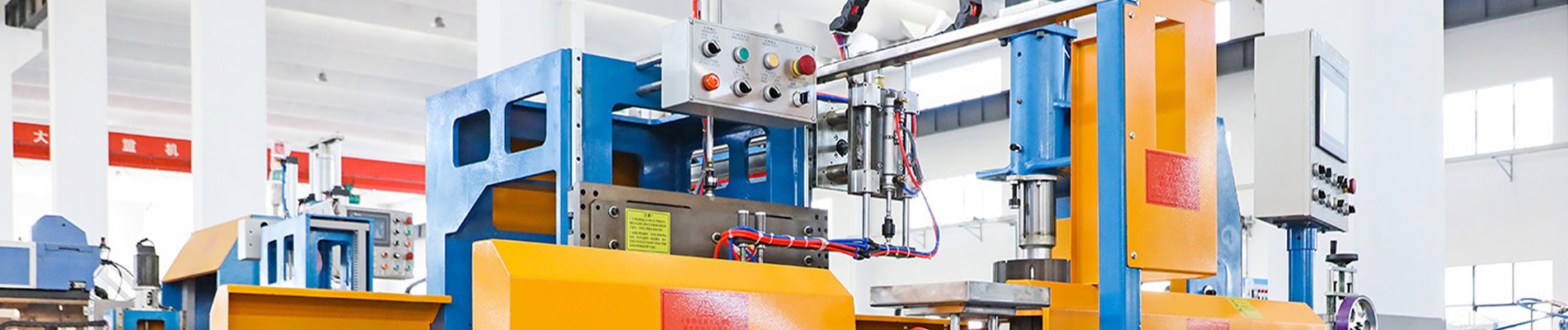

The wrapping mechanism of the machine is engineered for high - speed operation. It can wrap coils at a much faster rate compared to traditional machines. The advanced tension control system also ensures that the high - speed wrapping process does not affect the quality of the wrapping. It can maintain consistent tension even at high speeds, resulting in well - wrapped coils.

The machine is equipped with a quick - changeover system. This allows operators to switch between different coil sizes and wrapping requirements quickly. For example, if a production line needs to switch from wrapping small - diameter coils to large - diameter coils, the machine can be adjusted in a matter of minutes. This reduces downtime and increases overall production efficiency.

The conveyor and wrapping units of the machine are synchronized to work together seamlessly at high speeds. The conveyor moves the coils into the wrapping area at the right time and speed, ensuring a continuous and efficient wrapping process. This synchronization is crucial for maintaining the high - speed operation of the machine.

The high - speed operation of the machine significantly increases productivity. It can wrap a large number of coils in a short period, allowing industries to meet tight production schedules. This is especially beneficial for industries with high - volume production requirements, such as mass - produced wire and cable manufacturers.

With increased productivity, the cost per wrapped coil is reduced. The machine's high - speed operation means that more coils can be wrapped with the same amount of resources, such as labor and energy. This results in cost savings for the industries using the machine.

In the market, companies that use our high - speed coil wrapping machine can offer faster delivery times and more competitive pricing. This gives them an edge over their competitors, allowing them to capture a larger market share and grow their business.

Spec and Details:

| Height H (mm) | Outside Diameter O.D ( mm ) | Inside Diameter I D (mm) | Wire/Cable Diameter (mm) | Average output ( 100M / Coil ) |

CP1040 | 50-100 | Ø180-Ø400 | Ø120-Ø200 | Ø3 - Ø 8 | 2Coils/Min. |

CP1860 | 70-150 | Ø280-Ø600 | Ø180-Ø250 | Ø5 - Ø 15 | 1Coils/Min. |

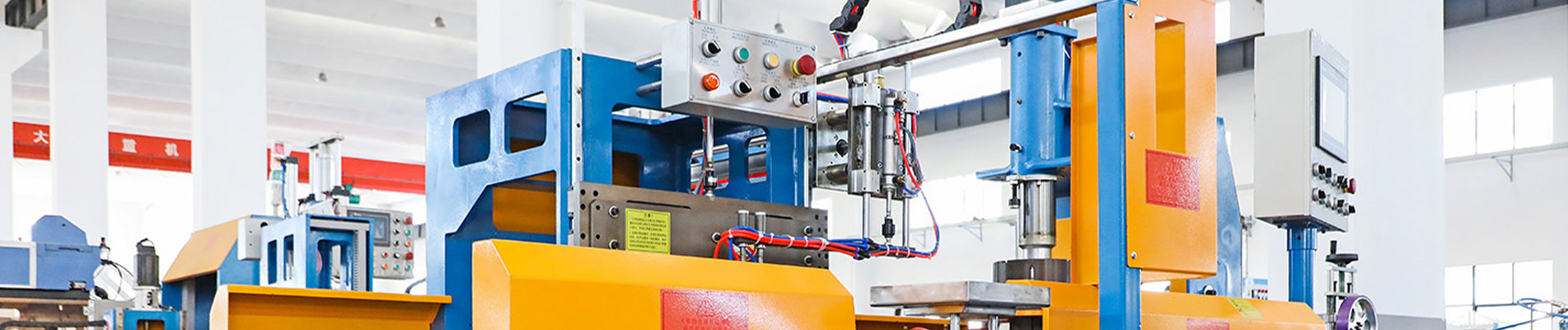

The wrapping mechanism of the machine is engineered for high - speed operation. It can wrap coils at a much faster rate compared to traditional machines. The advanced tension control system also ensures that the high - speed wrapping process does not affect the quality of the wrapping. It can maintain consistent tension even at high speeds, resulting in well - wrapped coils.

The machine is equipped with a quick - changeover system. This allows operators to switch between different coil sizes and wrapping requirements quickly. For example, if a production line needs to switch from wrapping small - diameter coils to large - diameter coils, the machine can be adjusted in a matter of minutes. This reduces downtime and increases overall production efficiency.

The conveyor and wrapping units of the machine are synchronized to work together seamlessly at high speeds. The conveyor moves the coils into the wrapping area at the right time and speed, ensuring a continuous and efficient wrapping process. This synchronization is crucial for maintaining the high - speed operation of the machine.

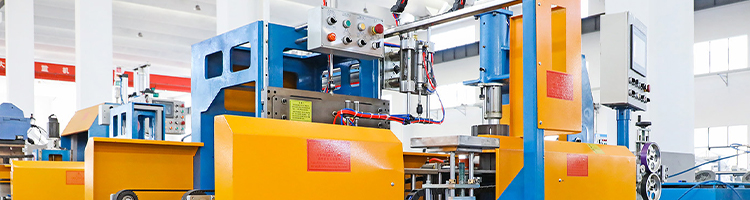

The high - speed operation of the machine significantly increases productivity. It can wrap a large number of coils in a short period, allowing industries to meet tight production schedules. This is especially beneficial for industries with high - volume production requirements, such as mass - produced wire and cable manufacturers.

With increased productivity, the cost per wrapped coil is reduced. The machine's high - speed operation means that more coils can be wrapped with the same amount of resources, such as labor and energy. This results in cost savings for the industries using the machine.

In the market, companies that use our high - speed coil wrapping machine can offer faster delivery times and more competitive pricing. This gives them an edge over their competitors, allowing them to capture a larger market share and grow their business.

Spec and Details:

| Height H (mm) | Outside Diameter O.D ( mm ) | Inside Diameter I D (mm) | Wire/Cable Diameter (mm) | Average output ( 100M / Coil ) |

CP1040 | 50-100 | Ø180-Ø400 | Ø120-Ø200 | Ø3 - Ø 8 | 2Coils/Min. |

CP1860 | 70-150 | Ø280-Ø600 | Ø180-Ø250 | Ø5 - Ø 15 | 1Coils/Min. |