close

Choose Your Site

Global

Social Media

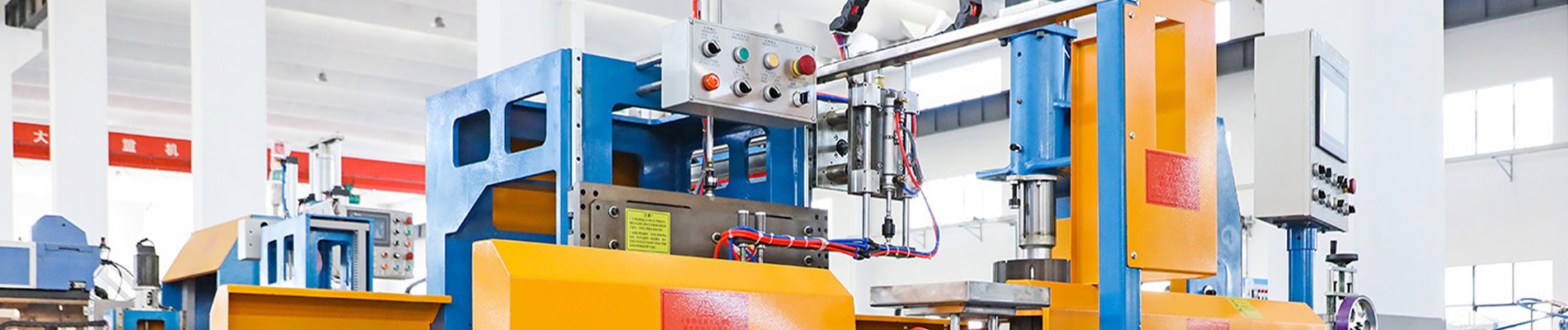

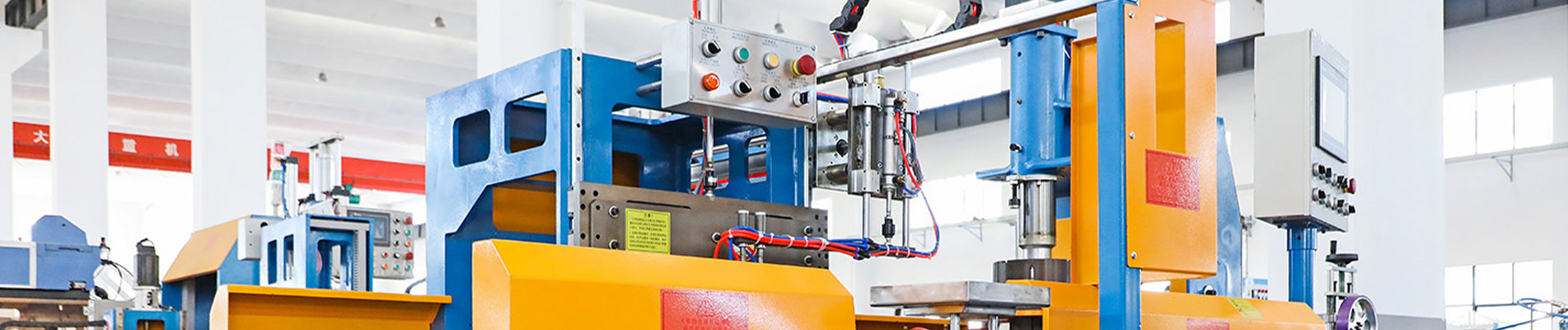

The device automatically wraps wires and cables into coils and binds them after wrapping. Typically, packaging materials such as PP film, paper tape, woven tape, and others are used.It binds 4ties of the coil to make sure coil more stable than one tie. When coil come to binding device

The tape will across the centre and tie it, after coil moved it will tie it again, that is two tie, after that the device will turn 90 degree around, then the binding device will do it again. Totally was 4ties. The is machine always accompany with sleeve shrink machine. It will be easy to take by the robot.

Automatic error detection: In case of equipment failure, the system will automatically identify the error and alert the operator to ensure smooth operation and maintenance.

Servo motor cable arrangement system: Utilize this system to achieve neat winding and optimal cable arrangement.

Wide range of applications: Suitable for high-speed automatic coiling and packaging of various wires and cables, including BV, BVR, RVV, UL electronic wires, flower wires, and more.

Unique design: The binding head can automatically tie circular objects, and when combined with a heat shrink machine, it provides perfect packaging.

These features enable the machine to offer high efficiency, automation, and labor savings in wire and cable production, leading to a significant improvement in production efficiency and product quality.

1. Auto-cable Coiling with continuous Strapping in one machine.

2. Non-Stop production enhances the efficiency and quantity.

3. Saving your space for installation,and reducing the man labor expense for cable package.

4. Could easily connect with Sleeve Heat shrink packing machine to do the packing continually

5. There will be whole in the centre of coil after packed, that will be easy taken by human or robot.

Model | Height(mm) | OD(mm) | ID(mm) | Wire Dia(mm) | Wrapping Materials | Average Coil output speed (100m/Coil) |

Four Tie Straps | ||||||

CZ1026 | 50-100 | 180-260 | 140 | 3-6 | PP Belt | 2-2.5coil/min |

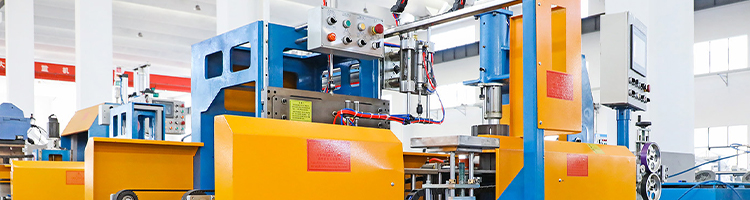

The device automatically wraps wires and cables into coils and binds them after wrapping. Typically, packaging materials such as PP film, paper tape, woven tape, and others are used.It binds 4ties of the coil to make sure coil more stable than one tie. When coil come to binding device

The tape will across the centre and tie it, after coil moved it will tie it again, that is two tie, after that the device will turn 90 degree around, then the binding device will do it again. Totally was 4ties. The is machine always accompany with sleeve shrink machine. It will be easy to take by the robot.

Automatic error detection: In case of equipment failure, the system will automatically identify the error and alert the operator to ensure smooth operation and maintenance.

Servo motor cable arrangement system: Utilize this system to achieve neat winding and optimal cable arrangement.

Wide range of applications: Suitable for high-speed automatic coiling and packaging of various wires and cables, including BV, BVR, RVV, UL electronic wires, flower wires, and more.

Unique design: The binding head can automatically tie circular objects, and when combined with a heat shrink machine, it provides perfect packaging.

These features enable the machine to offer high efficiency, automation, and labor savings in wire and cable production, leading to a significant improvement in production efficiency and product quality.

1. Auto-cable Coiling with continuous Strapping in one machine.

2. Non-Stop production enhances the efficiency and quantity.

3. Saving your space for installation,and reducing the man labor expense for cable package.

4. Could easily connect with Sleeve Heat shrink packing machine to do the packing continually

5. There will be whole in the centre of coil after packed, that will be easy taken by human or robot.

Model | Height(mm) | OD(mm) | ID(mm) | Wire Dia(mm) | Wrapping Materials | Average Coil output speed (100m/Coil) |

Four Tie Straps | ||||||

CZ1026 | 50-100 | 180-260 | 140 | 3-6 | PP Belt | 2-2.5coil/min |